Electronic Weigh bridge |

| |

| Types of Weigh bridge |

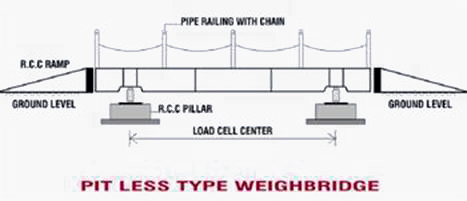

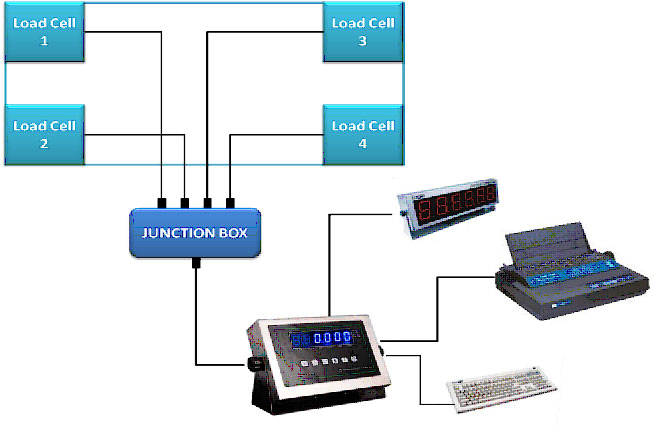

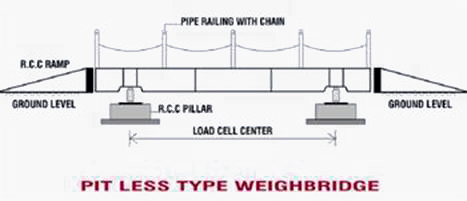

| | | 1 . Pit Less Type Weigh bridge | | |  | | | | | |  | | Normal Arrangement Of Pit Less Type Weigh bridge |

We manufacture high quality Pit less Weigh bridge These are mostly suitable where excavation work for foundation is difficult or construction of pit is expensive. Since the structure is above ground level, vehicles can approach the weigh bridge only from two directions where the ramps are provided. This type of weigh bridge requires more space. Pit less Weigh bridge has some unique benefits over other types of weighbridges. | | | Benefits : Costly pit construction is eliminated.- Platform above ground level- No water logging during rainy season

- Problem of pit maintenance is eliminated.

- Easy maintenance since all parts accessible above ground level.

| | | | In Pit less weigh bridge RCC ramp work must be required at least 3 meters for both side for easy movement of vehicle. |

|

|

| |

| 2. Pit Type Weigh bridge |

|

| |

|

| |

|

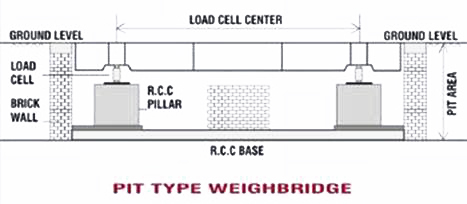

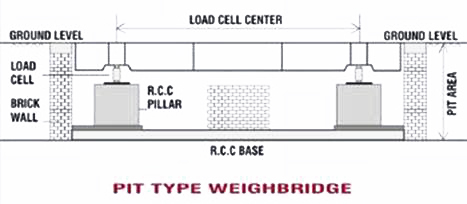

| Normal Arrangement Of Pit Type Weigh bridge |

We manufacture various types of weighbridges like Pit Type Weigh bridge This type of weigh bridge is most suitable for places with limited space like non-hilly areas as the construction cost there is rational. It saves a lot of money because at non hilly areas platform is in level with the ground, vehicles can approach the weigh bridge from any direction. Most public Pit Type Weigh bridge prefer this design as they require lesser space, rickshaws & tractor trolleys can also be weighed as platform is in flush with ground level and no ramp require for truck movement because it is installed in land surface level. |

Benefits - Lesser Space Required (As it has no ramps)

- Rickshaws & Tractor Trolleys can also be weighed as platform is in flush with ground Level.

- No Ramp require for truck movement because it is installed in land surface level

|

| |

SIZE AND CAPACITIES

|

| |

| |

| |

| |

| |

| |

| |

Platform Size( Mtr.) | Capacity (Ton) | Graduation (kg) | Number of Load cells | Size of Capacities | 4.5 X 2.5 | 10 | 2 Kg. | 4 | | 6 X 2.5 | 20 | 2 Kg. | 4 | | 7.5 X 3 | 30 | 5 Kg. | 4 | All models are available from 7.5 X 3m. up to

20 X 3m. | 9X3 | 40/50 | 5 Kg. | 4 | Standard capacities range from | 1OX3 | 40/50 | 5 Kg. | 4 | 20,000 up to

1,00,000 Kg Other | 12 X 3 | 50 | 5 Kg. | | Platform sizes and capacities also | 14 X 3 | 50/60 | 10 Kg. | 6 | possible to suit individual requirements | 15X3 | 50/60 | 10 Kg. | 6 | and regulations. Load cell range | 16 X 3 | 50/60 | 10 Kg. | 6 | includes explosion proof | 18X3 | 60/80/100 | 10 Kg. / 20 Kg | 8 | load cells also. | 20X3 | 80/100 | 10 Kg. / 20 Kg | 8 | | Specifications subject to change without notice |

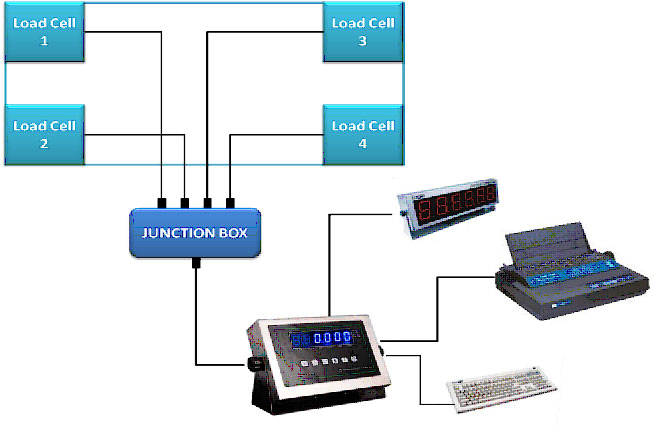

Features  Modular Form Modular Form |  Parallel out put to printer Parallel out put to printer |  96 KB switching memory battery backed 96 KB switching memory battery backed |  22 KB system software 22 KB system software |  Built in real time clock Built in real time clock |  100 year software calendar to display day, date, month, year, hours & minutes. 100 year software calendar to display day, date, month, year, hours & minutes. |  16 character single line & 20 character double line LCD module for user dialogue in a question / answer form. 16 character single line & 20 character double line LCD module for user dialogue in a question / answer form. |  25mm high 7 segment red led to weight 25mm high 7 segment red led to weight |  RS 232C for Interface Pc RS 232C for Interface Pc |  LCD output for jumbo display LCD output for jumbo display |  IBM compatible 104 key board ( ATÂ ) IBM compatible 104 key board ( ATÂ ) |

|

| |

Deteil's of Require Road Clearance For Weigh Bridge |

| |

|

| |

Weighbridge Size (Meters) | Road Clearance Required (Feet) | 4.2 x 2.4 m | 40 | 4.85 x 2.4 m | 50 | 6.09 x 2.4 m | 64 | 6.7 x 3 m | 70 | 7.5 x 3 m | 80 | 9 x 3 m | 100 | 10 x 3 m | 120 | 12 x 3 m | 150 | 14 x 3 m | 170 | 15 x 3 m | 175 | 16 x 3 m | 190 | 18 x 3 m | 200 | 20 x 3 m | 240 | 22 x 4 m | 260 |

|

| |

| WEIGHBRIDGE GENERAL ARRANGEMENT |

| |

|

| |

| |

No comments:

Post a Comment